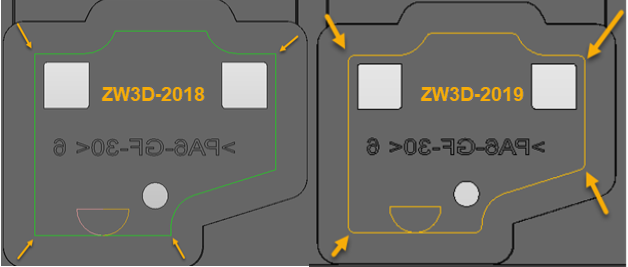

1. Smooth corner transition for 2-axis operation

In ZW3D 2019, arc control was added to optimize the tool path when dealing with contour corners.

Compared with ZW3D 2018, the tool path created in ZW3D 2019 is rounded at contour corners as the image shown below.

Figure 1. The comparison of the tool path of contour corners

These round trajectories can lengthen tool life, make the machining process smoother, and improve machining quality.So, how to set a desired radius? In ZW3D 2019, you can set a suitable value for Side Finish Radius to generate the tool path with round corners.

Figure 1. The comparison of the tool path of contour corners

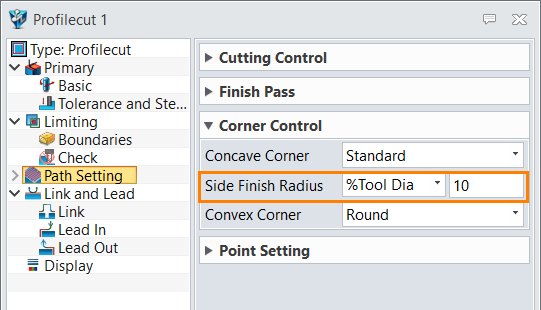

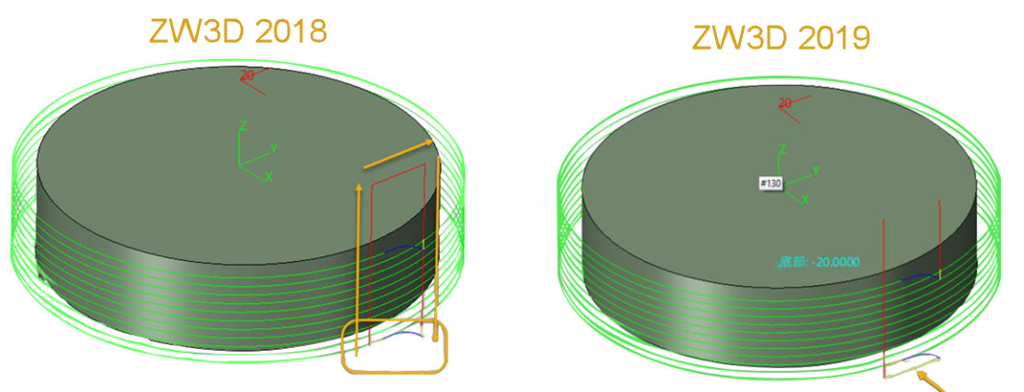

2. Optimized lead-in tool path for Helical Cut

In the 2018 version, the lead-in tool path is under the horizontal plane, which may cause the failure of infeed. Now the lead-in tool path is above the horizontal plane, bringing forth ideal helical cutting results.

Figure 3. The comparison of tool path for Helical Cut

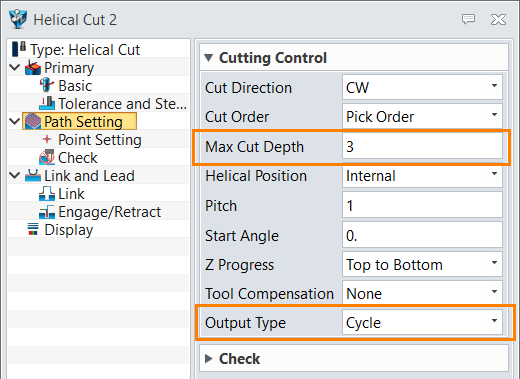

Besides, the control of machining depth is more flexible with Max Cut Depth and Output Type, which can be set according to the machining requirements as shown below.

Figure 4. Path Setting of Helical Cut

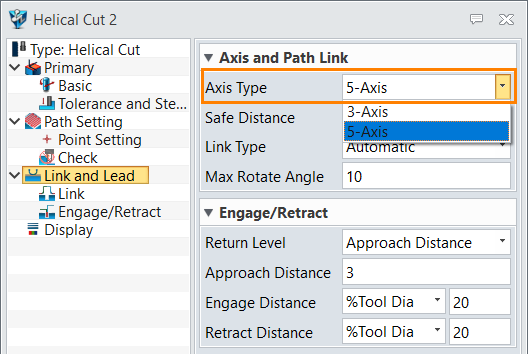

Moreover, ZW3D 2019 supports Helical Cut not only for 3-axis but also for 5-axis machining.

Figure 5. Switch axis types in Axis and Path Link

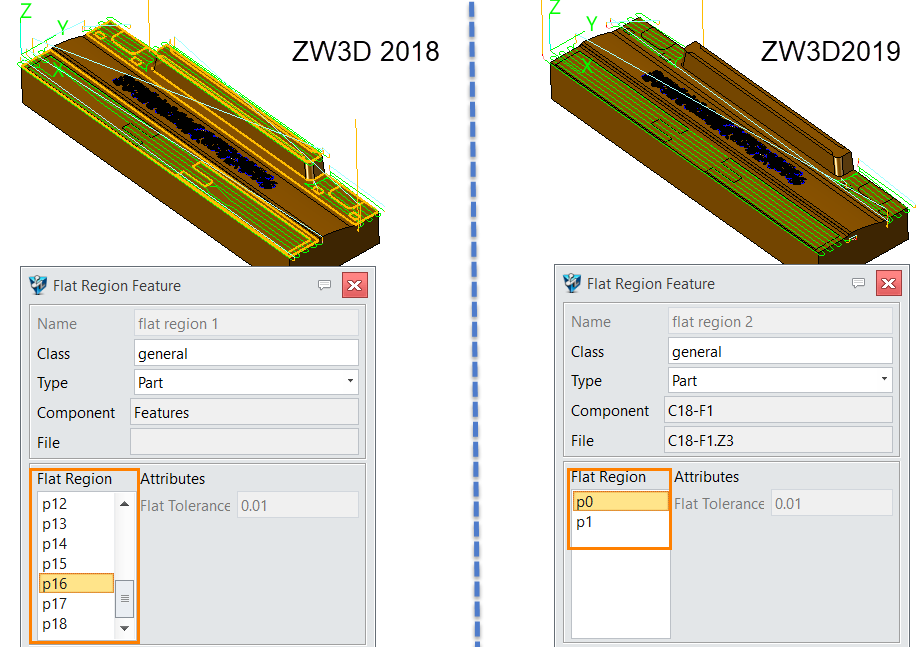

3. Smarter feature detection of Flat Region

Previously, when we define the flat region of a part for Flat Finish operation, a lot of facets will be mistakenly detected due to some division lines.

Now in ZW3D 2019, the boundaries can be intelligently chosen to deliver neat trajectories as shown in figure 6, so that the flat region can be recognized and selected correctly.

Figure 6. The comparison of flat region detection

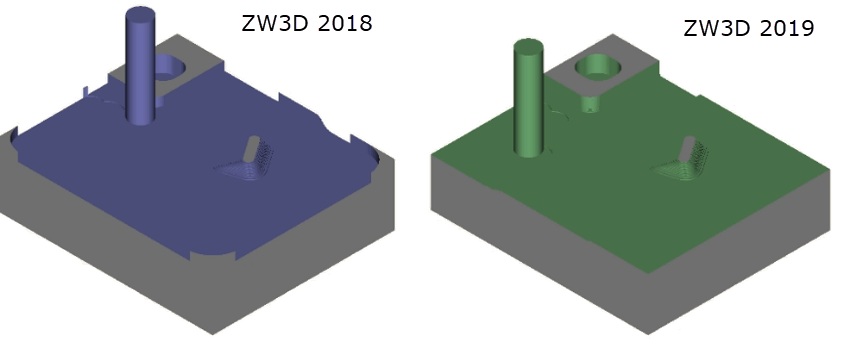

4. More reliable big-step cutting without residues

In the previous version, when the stepover of 3-axis roughing exceeds 80% of tool diameter, there will be residues after Rough Offset operation.

Now, as the right picture of figure 7 shows, the part after being roughed is perfect without residues in ZW3D 2019 thanks to the upgraded big-step cutting, delivering more reliable roughing results.

Figure 7. Residue comparison after big-step roughing

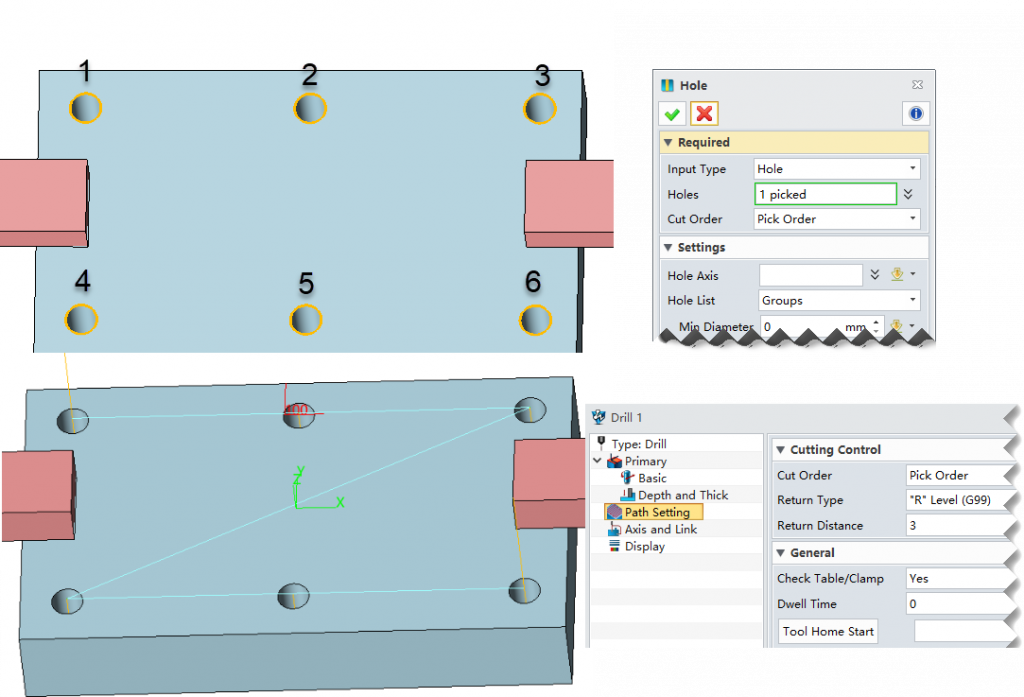

5. Improved cut order for hole feature

In actual machining, it would be convenient if we can set the drilling sequence flexibly. In 2019 SP version, the hole processing sequence can be customized. The Cut Order can be decided by Pick Order, which means that the holes will be processed according to the Pick Order.

Figure 8. Hole processing according to the customized sequence

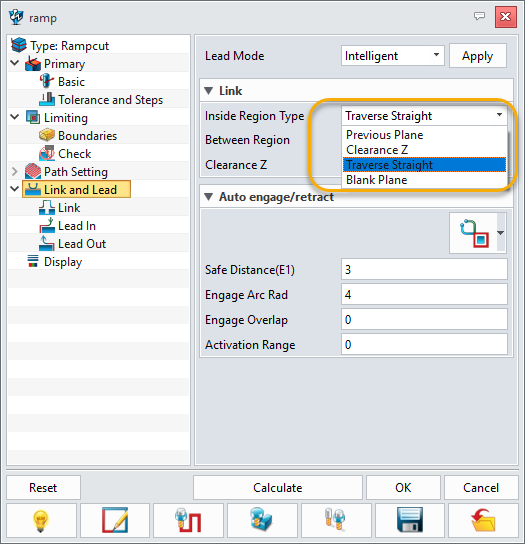

6. Optimized link types

Traverse Straight has been added to the last cut of processing, which can reduce unnecessary links to improve the efficiency of cutting ramp.

Figure 9. Optimized link

Figure 10. Select Traverse Straight as Inside Region Type to improve cutting efficiency